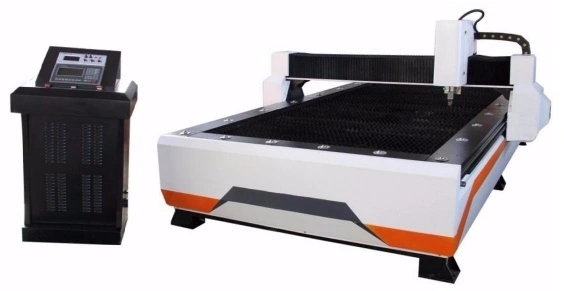

Castaly Machinery offers a couple different CNC Plasma Machines. Please refer to features and specifications of each to find the one that best meets your needs.

Features:

All “servo motor” driving system: All axis are driven by brush-less type, high torque AC servo motors.

Working mode; untouched arc striking. Auto cutting height adjustment by system for the best cutting result.

Auto height protection for safety & fast production.

A variety of Hypertherm Powermax torch styles provide exceptional versatility for hand cutting or gouging, portable automation, X-Y table and robotic cutting or gouging.

Finish jobs faster with cut speeds two and a half times greater than oxy / fuel on 1/2" mild steel.

Spend less time on grinding and edge preparation due to superior cut and gouge quality.

No need to change the air pressure; Smart Sense technology ensures that it is always correctly set.

Drag cut at full output with a patented shield that reduces dross buildup for smoother cutting.

Tackle different jobs with multiple, easy-to-use torch styles.

Reduce costs with long consumable life and more up time.

High power efficiency lowers energy consumption.

Spring Start technology ensures consistent starting and a more reliable torch.

Low maintenance for maximum up time.

DSP CNC controller is setup to accept standard G-code programming formats along with on board conversational applications.

Optional CAD/CAM system can create and edit part programs then send to machine for easy cutting. DXF files can be imported, modified and edited from here to create a G-code.

Moving gantry construction for space saving.

The rigid steel frame construction has been stress relieved prior to finish machining to provide repeat-ability and accuracy.

Linear guides and sliding blocks are prismatic pre-loaded with recirculation bearings to ensure maximum rapid traverse and precision.

The X & Y axis are equipped with a precision rack & pinion driving system.

The Z axis utilizes a ball screw assembly complete with the pre-loaded and ground screw for long life and optimum accuracy.

Specifications:

Control System

DSP Control with USB Interface

Command Language

G Code

Lathe Frame

Heavy-duty Metal Welding

Driving System

Japan Yaskawa Servo Drive & Motor

X,Y Axis Structure

Helical Rack & Pinion Drive

Z Axis Structure

Taiwan TBI or HIWIN Ball Screw

X Y X Axis Square Rails

Taiwan HIWIN Brand Linear Rails

Electric Parts

France Schneider

Limited Switch

Japan Omron

Machine Working Size

X * 55”, Y * 98”, Z * 4”

Machine Size (L x W x H)

126” x 84” x 56”

Machine Max. Travel Speed

590 IPM

Machine Max. Cutting Speed

196 IPM

Machine Power

3 PH, 220 V

Machine Weight

3,510 lbs.

CAD / CAM Drawing Software

Optional

Options:

PLASMA-5598C: China Generator

PLASMA-5598HP: Hypertherm Powermax 85 Generator

We use cookies to improve your experience. Privacy Policy.